The PFA injection molding process is an important process for producing PFA material. If you are a fluoropolymer Injection Molding manufacturer or you want to know how to injection mold a PFA component, this article will tell you what you need to care about.

The PFA injection molding process includes 7 steps.

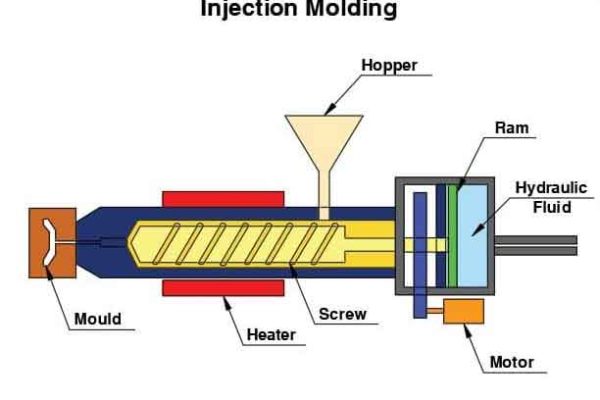

- Feeding the raw material PFA resin into the extruder.

- Heating to the melt.

- Screw extrusion material.

- Molding through the mold.

- Cooling and shaping.

- Cutting pipe fittings.

- Packing.

The whole process requires serious control of every step to ensure product quality.

Choosing the suitable Material for PFA injection molding

Low MFR PFA materials are more dense and do not flow as easily during processing. The high MFR PFA materials flow better and are easier to mold and process into shapes.

so we always choose the PFA materials with an MFR of 16~30g/10min.

Choosing the right injection molding machine and mold

If you choose the wrong injection molding machine, there may be some problems. such as

- Black spots or black color in the PFA components.

- Damage to the injection molding machine.

- Damage the health problems.

So it is necessary to choose a suitable injection molding machine.

PFA injection mold needs to choose a screw molding machine with large and powerful. When we heat the PFA, it will release hydrofluoric acid, which is dangerous to breathe and will damage the machine. so Stronger security is required for the machine. An exhaust system, and nickel-based alloy or 2316 chrome nitride-plated screw are needed.

Molds should be the same material as the screw.

how to control the PFA injection molding process?

- Dry Material: The PFA Resin should be Dry at 100-200 degrees for 2 hours.

- Preheating the mold: Before injection, we need to preheat the mold to 150-220 degrees to ensure that the temperature matches the injection.

- Injection Molding Temperature: PFA’s melting temperature is above 305°C. and the heating temperature should be between 260°C and 330°C. If the heat temperature is too high or too low, it will affect the PFA component.

- Injection Pressure: To ensure the material can fill the cavity and eliminate air, injection molding PFA needs high pressure. The injection pressure should be adjusted according to the PFA material’s flow and the product’s size and shape. Typically, it should be between 800 and 1200 bar.

- Injection speed: The injection speed should generally be between 50 and 100 mm/s.

- Holding Time and Pressure: The holding time is usually between 20 and 60 seconds. Pressure is usually between 80 and 120 bar. Note: Long holding times and pressures may cause distortion and cracking.

- Cooling time: The cooling time is between 20 and 40 seconds. To prevent the PFA component, the temperature should be slowly cooling down

The Advantages and Applications of Injection

Injection Molded PFA is widely used in Semiconductor Applications, Chemical, and Healthcare industries.

It will be used more and more in the new industries, so we need to improve the PFA injection molding technical asap.

If you want to know more about PFA injection or PFA Material, please contact us feel free.

FAQ

- why my PFA component deformity?

- the injection process with high Temperature.

- why my PFA component is yellow?

- You need to down the heat temperature.

- Why is the PFA component black black spot?

- The workshop is not clean, need a clean room.

- The machine is PFA only, don’t inject other material.

- The injection molding machine screw should be cleaned

- Choose good PFA material.