Компрессионное формование — это экономически эффективный метод создания прочных, сложных деталей с использованием тепла и давления.

Компрессионное формование подразумевает помещение предварительно нагретого материала в полость формы и приложение к нему давления для придания ему формы по мере его затвердевания под воздействием тепла.

Этот процесс идеально подходит для производства крупных деталей с минимальными отходами, хотя он может вызывать проблемы с однородностью и сложностью конструкции.

Что такое компрессионное формование и как оно работает?

Компрессионное формование[^1] — это мощная технология, позволяющая придавать материалам желаемую форму. Она сочетает в себе нагрев, давление и время для создания прочных деталей.

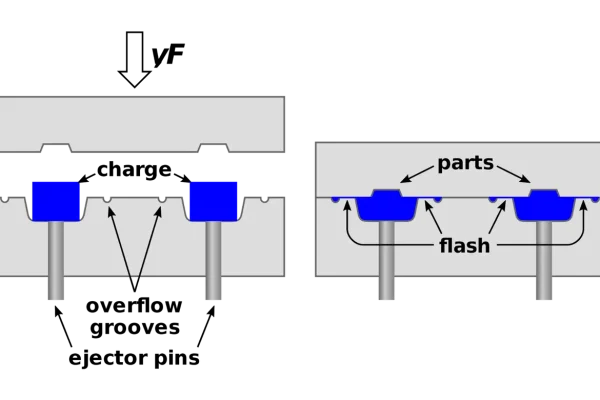

Компрессионное формование подразумевает размещение предварительно нагретого материала в открытой полости формы. Затем форма закрывается под давлением, позволяя материалу затвердеть и принять нужную форму. Этот метод эффективен для производства крупных деталей с минимальным количеством отходов.

Эффективное формование материалов с минимальными отходами

Процесс начинается с выбора правильного материала, часто термореактивные материалы или термопласты[^2] например, эпоксидная смола или полипропилен. Предварительно нагретый материал помещается в форму, которую затем плотно закрывают. Нагрев и давление применяются до тех пор, пока материал не затвердеет, образуя цельное изделие. После охлаждения изделие можно извлечь из формы.

Одним из ключевых преимуществ компрессионного формования является его экономичность по сравнению с другими методами, такими как литье под давлением. Это позволяет производить высокопрочные детали, подходящие для автомобильные и аэрокосмические приложения[^3]. Однако при создании сложных дизайнов могут возникнуть ограничения из-за возможных деформаций во время отверждения.

| Преимущества | Ограничения |

|---|---|

| Низкие затраты на установку | Более длительное время цикла |

| Минимальные материальные отходы | Ограничено простыми формами |

| Отличная отделка поверхности | Проблемы со сложными проектами |

В целом, компрессионное формование остается популярным выбором для производителей, стремящихся эффективно производить долговечные детали и при этом эффективно управлять затратами.

Почему стоит выбрать компрессионное формование, а не другие методы?

Компрессионное формование[^4] — разумный выбор для производителей, стремящихся к эффективности и экономии средств. Он минимизирует отходы и снижает производственные затраты, что делает его привлекательным вариантом.

Компрессионное формование отличается низкими затратами на установку и минимальными отходами материала по сравнению с литьем под давлением или литьем под давлением. Этот метод идеально подходит для производства крупных деталей с превосходной отделкой поверхности, особенно в таких отраслях, как автомобилестроение и аэрокосмическая промышленность.

Процесс компрессионного формования

Процесс компрессионного формования включает в себя помещение предварительно нагретого материала в открытую полость формы, после чего материал подвергается воздействию тепла и давления до затвердевания. Этот метод особенно эффективен для термореактивные смолы[^5] и позволяет создавать сложные конструкции с армированием стекловолокном. В отличие от литья под давлением, которое может потребовать дорогостоящих пресс-форм и более длительного цикла, компрессионное формование позволяет быстрее перестраивать производство. Кроме того, оно образует меньше отходов, что делает его более экологичным. Однако важно отметить, что, несмотря на превосходные результаты компрессионного формования во многих областях, оно может столкнуться с проблемами, связанными с однородностью продукции и сложностью конструкции. В целом, его преимущества делают его предпочтительным выбором для множества применений в различных отраслях промышленности.

Какие материалы лучше всего подходят для компрессионного формования?

Компрессионное формование — это эффективный метод формования материалов под воздействием тепла и давления. Хотите узнать, какие материалы лучше всего подходят для этого процесса?

Основными материалами, используемыми при компрессионном формовании, являются термореактивные материалы и термопласты. Термопласты нравиться ПТФЭ, ФЭП, ПФА, ЭТФЭ, PEEK, и Смолы PCTFE. Это может менять форму при нагревании. Каждый материал обладает уникальными свойствами, которые делают его пригодным для различных применений: от автомобильных деталей до потребительских товаров.

Формовочные термопласты

Выбор материала существенно влияет на прочность, долговечность и пригодность конечного продукта к применению. Например, термореактивные смолы Идеально подходят для высокопрочных компонентов благодаря своей превосходной термостойкости. Их часто используют автомобильная и аэрокосмическая промышленность где производительность имеет решающее значение. С другой стороны, термопласты обеспечивают гибкость В дизайне они незаменимы, поскольку их можно нагревать и менять форму. Это делает их подходящими для изготовления сложных деталей со сложными конструкциями.

Кроме того, использование таких волокон, как стекловолокно или углеродное волокно, дополнительно улучшает механические свойства. Сочетание этих материалов позволяет производителям эффективно производить лёгкие, но прочные компоненты. Понимание этих возможностей помогает компаниям выбирать материал, соответствующий их конкретным потребностям, оптимизируя при этом производственные затраты и результаты.

Как компрессионное формование применяется в различных отраслях промышленности?

Компрессионное формование[^9] — это революционный процесс для многих отраслей. Он эффективно формует материалы, сокращая при этом отходы, но как он вписывается в различные отрасли?

Компрессионное формование широко используется в автомобильной, аэрокосмической и потребительской промышленности. В автомобильной промышленности он создает прочные детали, такие как капоты и крылья, с использованием таких материалов, как стекловолоконная смола. Авиационно-космическая промышленность включает производство легких компонентов, выдерживающих высокие нагрузки. Потребительские товары также выигрывают от этого процесса: такие предметы, как кухонная утварь, производятся более эффективно.

Компрессионное формование для получения прочных деталей

Универсальность компрессионного формования делает его пригодным для различных отраслей промышленности. автомобильное производство[^10] Крупногабаритные детали изготавливаются быстро и экономично. Например, компании используют системы полиэфирных стекловолоконных смол для создания прочных автомобильных компонентов. В аэрокосмической промышленности потребность в лёгких, но прочных материалах стимулирует использование современных композитов, изготавливаемых методом компрессионного формования. Потребительские товары также получают преимущества: такие изделия, как насадки для детских бутылочек, производятся с высокой точностью и эффективностью.

Вот краткое сравнение приложений в этих отраслях:

| Промышленность | Примеры продуктов | Использованные материалы |

|---|---|---|

| Автомобильный | Капоты, крылья | Полиэфирная стекловолоконная смола |

| Аэрокосмическая промышленность | Компоненты самолетов | Современные композитные термопласты |

| Потребительские товары | Кухонные принадлежности, насадки на детские бутылочки | Термореактивные смолы |

В целом, возможность компрессионного формования производить крупные детали с минимальным количеством отходов делает этот процесс важнейшим в различных отраслях.

Заключение

Компрессионное формование позволяет эффективно формовать материалы с помощью тепла и давления, что идеально подходит для автомобильной и аэрокосмической промышленности благодаря экономической эффективности и минимальному количеству отходов.