Peflon supplies PCTFE material from manufacturer-controlled production, supporting distributors and plastic processing factories that depend on consistent batches and long-term programs.

PCTFE material supplied directly from manufacturer

Built for repeat orders, not one-off trials

Suitable for regulated and sealing applications

What is PCTFE, and why choose it?

PCTFE (also named polychlorotrifluoroethylene, alias Kel-F / Neoflon) is a melt-processible fluoropolymer with ultra-low moisture permeability and excellent dimensional stability. As a transparent barrier polymer, PCTFE can be made into film, resin, sheet, and custom shapes. It meets FDA, ISO, and RoHS standards in many grades. At Peflon, we offer over a decade of PCTFE manufacturing experience with GMP clean production lines and multiple production lines in China. Our strengths include custom formulation, strict QA testing, full data sheet support, and fast global logistics. For pharmaceutical, cryogenic, or semiconductor use, PCTFE from Peflon ensures stable barrier, mechanical reliability, and supply security — request a quote today.

| Property | Typical Value | Test Method / Condition | Notes |

|---|---|---|---|

| Density | 2.10–2.17 g/cm³ | ASTM D792 | Slightly higher than PTFE |

| Tensile Strength | 40–50 MPa | ASTM D638 | High mechanical rigidity |

| Elongation at Break | 5–15% | ASTM D638 | Good toughness at low temps |

| Flexural Modulus | 1,000–1,300 MPa | ASTM D790 | Excellent stiffness |

| Melting Point (Tm) | 210–215 °C | DSC | Stable crystalline structure |

| Glass Transition (Tg) | 45 °C | DSC | Ensures rigidity at room temp |

| Service Temperature | −200 °C to +190 °C | — | Retains shape at cryogenic range |

| Coefficient of Thermal Expansion (CTE) | 5 × 10⁻⁵ /°C | ASTM E831 | Low dimensional change |

| Water Vapor Transmission Rate (WVTR) | 0.04 g·mm/m²·day | ASTM F1249 | Exceptional moisture barrier |

| Dielectric Constant (1 MHz) | 2.1–2.3 | ASTM D150 | Stable insulation in electronics |

| Volume Resistivity | 10¹⁶ Ω·cm | ASTM D257 | Excellent electrical insulation |

| Flammability | Self-extinguishing | UL 94 V-0 | High safety index |

PCTFE offers a very low thermal expansion rate, giving you predictable dimensions even when temperature changes quickly. This makes PCTFE rod and PCTFE sheet highly suitable for tight-tolerance sealing parts.

PCTFE machines cleanly with standard CNC tools. You can achieve sharp edges, smooth surfaces, and uniform thickness without the cold flow that occurs in softer fluoropolymers.

Because PCTFE can be made in clear or translucent form, it is often used in instruments that require visual inspection, liquid viewing, or sample containment.

PCTFE resists stress cracking better than many plastics, which helps extend service life in oxygen systems and compressed-gas equipment.

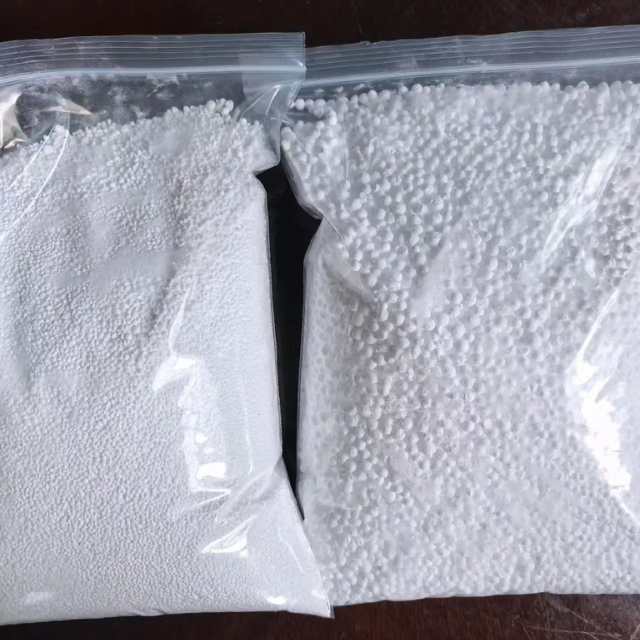

Peflon supplies high-purity PCTFE raw materials, available in resin pellets and fine powder grades. Each form is engineered for different processing methods—such as injection molding, extrusion, and rotational molding—and provides the stability, low permeability, and consistency required in critical applications. As a China-first PCTFE manufacturer, we ensure stable supply, ISO-certified quality, and technical support for your production.

As a versatile fluoropolymer, PCTFE resin and powder from Peflon are used across industries that demand extreme reliability, low permeability, and thermal stability. Whether you’re developing medical packaging, cryogenic systems, or semiconductor components, PCTFE ensures consistent performance, long-term durability, and compliance with global standards.

PCTFE offers a unique balance of stiffness, clarity, and clean handling compared with other fluoropolymers. This makes PCTFE sheets and PCTFE rods suitable for parts that require steady shape and low surface change during long operation cycles.

Yes. PCTFE material performs well in oxygen systems because it does not shed particles easily and stays stable under pressure. Many buyers use PCTFE parts for oxygen valves, gas regulators, and medical testing tools.

You can machine PCTFE rod or mold PCTFE pellets. Both methods work, and the right choice depends on your shape and volume. Machining suits tight-tolerance parts, while molding fits repeat orders and simple designs.

PCTFE sheets and rods should be kept in clean, dry storage away from heat and sharp tools. The material does not absorb much moisture, but proper storage helps keep surfaces free from scratches before machining.

Yes. Peflon supports custom PCTFE machining and molding. You can send your drawing, preferred diameter, or thickness, and we will prepare a sample or quote based on your project.

If you are comparing PCTFE with other fluoropolymers for heat, strength, or long-term durability, you can also review our PTFE, FEP, PFA, and ETFE product lines. These materials give you different levels of flexibility, clarity, temperature resistance, and chemical stability. Each option helps you match your design needs without extra trial time or unexpected changes. Explore these materials to find the right alternative or companion product for your project. Contact us if you need help choosing the best grade.

If you need clear guidance while testing or selecting PCTFE materials, our team provides easy-to-follow support for engineering, quality, and R&D work. You can access setup tips, machining notes, storage instructions, and comparison guides that help you avoid delays during evaluation. We also share practical articles on PCTFE design and application cases so your team can make faster decisions with less trial-and-error. Visit our technical blog to read the latest resources or request specific support for your project.

If you need a clear quote or technical advice for your PCTFE project, our team is ready to help. You can send your drawings, size requirements, or application details, and we will prepare the right material option for your needs. Please fill out the form on the right, and our sales engineer will reply within 24 hours with pricing, lead time, and sample information. Tell us how you plan to use PCTFE, and we will guide you to the best solution.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.