Peflon PTFE Aqueous Dispersion is

Teflon dispersion, also named PTFE Emulsion a milky-white or light-yellow liquid; The particle size is between 0.2-0.4 μm. TFE, water, and 2.0-7.0% non-ionic surfactant produce it(not PFOA).

The PTFE Emulsion is 60% dispersion of PTFE in water

The pH is between 8 and 10.

3M, Teflon, GFL, AGC, and DAIKIN are famous ptfe aqueous dispersion suppliers.

PTFE Dispersion, also named PTFE aqueous dispersion or PTFE emulsion, is a water-based system where fine PTFE particles are uniformly dispersed for use in coating and impregnation processes. You typically evaluate PTFE Dispersion when your application requires liquid processing rather than solid PTFE forms.

Peflon PTFE Dispersion is developed for customers who need clear specifications, traceable compliance files, and repeatable supply for qualification and scale-up. With years of experience in fluoropolymer manufacturing and dedicated dispersion production lines, we support technical evaluations, OEM sourcing, and long-term distribution programs.

When you evaluate PTFE Dispersion, properties and characteristics are used to confirm process fit, formulation compatibility, and documentation completeness. At this stage, you compare measurable parameters rather than application results, using data to reduce uncertainty before trials and qualification.

| Grade | Main Characteristics | Typical Applications | Compliance & Notes |

|---|---|---|---|

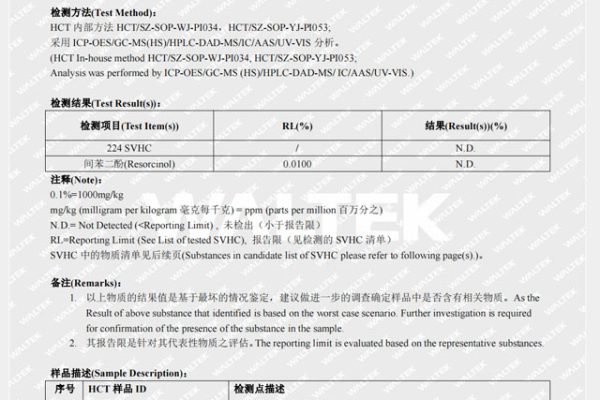

| PF-DF | Modified aqueous PTFE dispersion with balanced solid content and stable surfactant system. Designed for heat resistance and chemical permeability resistance. | High-grade nonstick top coatings. | PFOA-free, REACH / RoHS / SVHC / Food Contact compliant. |

| PF-DW | Modified PTFE dispersion with optimized particle stability and uniform film formation, suitable for smooth nonstick topcoat systems. | Nonstick cookware topcoats and water-based fluoropolymer coating systems. | PFOA-free, REACH / RoHS / FDA compliant. |

| PF-DD | Fine-particle PTFE dispersion with controlled particle diameter and low viscosity, supporting stable impregnation processes. | Glass fiber impregnation and technical insulation materials. | REACH / RoHS / SVHC certified. |

| PF-DP | High-stability PTFE dispersion with small particle size and broad temperature resistance, offering chemical inertness and electrical insulation. | Nonstick primer coatings, PTFE spinning, and specialty processing. | PFOA-free, REACH / RoHS / FDA compliant. |

Peflon provides many types of PTFE Dispersion, different grade Teflon emulsion have different application.

PF-DF, Same as 3M Dyneon TF 5035

Nonstick cookware coatings

Bakeware surface coatings

Multi-layer nonstick systems

PF-DD

Fiberglass fabrics

Technical textiles

Insulation materials

PF-DD

Conveyor and roller coatings

Industrial surface protection

Functional coating systems

PTFE Dispersion for primer coatings is selected when PTFE is used as a base layer within multi-coat systems

PTFE-impregnated gland packing

Braided sealing packings

Industrial valve and pump sealing materials

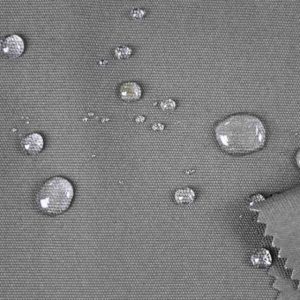

This dispersion exhibits remarkable non-stick attributes, corrosion resistance, and excellent thermal stability. It can reduce surface tension, improve chemical resistance, and improve release in many applications.

Its low coefficient of friction and exceptional dielectric properties make it an ideal choice in demanding environments.

Siverra lectus mauris ultrices eros in. Eget egestas purus viverra accumsan in nisl nulla nisi scelerisque euvestibulum sed.

Siverra lectus mauris ultrices eros in. Eget egestas purus viverra accumsan in nisl nulla nisi scelerisque euvestibulum sed.

Siverra lectus mauris ultrices eros in. Eget egestas purus viverra accumsan in nisl nulla nisi scelerisque euvestibulum sed.

Siverra lectus mauris ultrices eros in. Eget egestas purus viverra accumsan in nisl nulla nisi scelerisque euvestibulum sed.

From the chemical industry to surface treatment applications, PTFE dispersion is used in coatings, packing, coated glass cloth, coated fabric glass, non-stick coatings, dust control, outdoor cloth, architectural tensile membranes, and food conveyors.

PTFE dispersion in the manufacturing of dust control bags effectively enhances filtration efficiency, chemical resistance, high-temperature durability, while reducing pressure drop and energy consumption.

utilized in sealing applications for valves, pumps, and glands.

Binder for battery anode or cathode matrixes

The production involves emulsion polymerization, creating a stable dispersion suitable for diverse applications. Understanding this process aids in optimizing product quality.

This comprehensive exploration of PTFE dispersion aims to illuminate its multifaceted significance and influence across industries, catering to the diverse needs of businesses seeking high-performance materials for their operations.

PTFE Dispersion is coated onto other materials like metal or fiberglass and sintering at high temperatures.

Impregnating glass fabrics with PTFE dispersion, then sintering to make coated tensile membranes

Blend PTFE with plastic, process uniformly, test for effective anti-drip properties in manufacturing.

When comparing PTFE Dispersion suppliers, the difference lies not only in the material itself, but also in how well the supplier supports evaluation, qualification, and long-term supply. Peflon PTFE Dispersion is developed for customers who need predictable data, consistent processing behavior, and clear documentation throughout the sourcing process.

We provide SDS compliance with locally regulations, with UFI NO.

PTFE Dispersion quality testing at Peflon is aligned with how technical teams actually evaluate materials. Instead of generic checks, testing focuses on parameters relevant to handling, storage, and formulation screening.

Incoming and in-process quality checks

Consistency monitoring across production lots

Documentation prepared for technical review

One common risk during PTFE Dispersion sourcing is reformulation after supplier change. Peflon supports customers by aligning material behavior early in the evaluation stage, helping reduce unnecessary reformulation cycles.

Early-stage technical alignment

Clear communication on material behavior

Support during qualification and scale-up

When you evaluate PTFE Dispersion, the focus is usually on handling behavior, storage stability, and compatibility with your existing formulation system. Technical teams often start with small-scale trials to observe mixing, application, and drying behavior before moving to pilot production.

Yes. PTFE Dispersion is commonly used in coating systems as well as impregnation processes such as fiberglass fabrics or gland packing materials. The key is selecting a dispersion category that matches your process route rather than treating all PTFE dispersions as interchangeable.

During sourcing, buyers usually request PTFE Dispersion technical data sheets, safety data sheets, and compliance declarations. These documents support internal review, regulatory checks, and supplier qualification before approval.

In some cases, PTFE Dispersion can be adjusted to better align with formulation or processing needs. Customization is typically evaluated during the early technical assessment stage and confirmed through sample testing before any production commitment.

PTFE Dispersion should be stored in sealed containers under controlled conditions to maintain its original properties. Gentle mixing before use and avoiding extreme temperatures help ensure consistent behavior during evaluation and testing.

Batch-to-batch consistency of PTFE Dispersion is influenced by dispersion process control, raw material stability, and production monitoring. During evaluation, buyers often compare multiple batches to confirm reproducibility before approving long-term sourcing.

PTFE Dispersion may experience settling over time if stored or transported improperly. For evaluation purposes, technical teams typically review re-dispersibility and handling behavior after transport to ensure the material remains suitable for processing.

Although PTFE Dispersion products may appear similar on paper, they are not always interchangeable in real processing conditions. Differences in dispersion systems and formulation behavior often require validation tests before switching suppliers.

In multi-layer systems, PTFE Dispersion is evaluated based on how it interacts with adjacent coating layers. Technical teams usually focus on compatibility and processing sequence rather than treating the dispersion as a standalone material.

The evaluation timeline for PTFE Dispersion depends on internal testing protocols, application complexity, and documentation review. Many buyers complete initial screening within weeks, followed by extended trials before final approval.

When you use PTFE Dispersion in production, material selection often extends beyond a single product. For end-use manufacturers, related fluoropolymer materials help align coating performance, impregnation efficiency, and long-term process stability.

For nonstick coating factories, PTFE Dispersion is commonly evaluated alongside PTFE micropowders and binder-compatible additives to support primer, mid-coat, and topcoat systems. Reviewing related products helps you balance surface requirements and production consistency.

For PTFE gland packing manufacturers, PTFE Dispersion is often used together with PTFE fine powders or yarn treatments during fiber impregnation and finishing steps. Selecting compatible materials reduces process adjustment during braiding and drying.

For fiberglass fabric impregnation plants, PTFE Dispersion may be combined with PTFE fine powders or auxiliary fluoropolymer systems to support coating build-up and fabric penetration control.

Explore related PTFE materials to complete your process design and evaluation.

When you work with PTFE Dispersion in daily production, technical questions often arise during formulation trials, process adjustment, and scale-up. Peflon provides application-focused technical support to help end-use manufacturers address real production challenges.

For nonstick coating factories, technical resources cover coating layer design, dispersion handling during mixing, and process consistency across batches. For PTFE gland packing manufacturers, support focuses on fiber impregnation behavior, drying control, and stable processing during braiding and finishing. For fiberglass fabric impregnation plants, technical guidance helps optimize penetration behavior and coating build-up during continuous operations.

Our technical blog and application notes are designed to support your evaluation and production stages with clear explanations and practical insights.

Visit our PTFE Dispersion technical resources to support your production decision

If you are evaluating PTFE Dispersion for coating, impregnation, or sealing applications, clear communication at the early stage helps reduce trial time and process uncertainty. Whether you are running formulation tests, reviewing documentation, or preparing for scale-up, sharing basic project details allows for more effective technical discussion.

Tell us about your application. Our team will support your next step.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.