Introduction: The Importance of FEP Material and Extrusion Processing

- FEP (Fluorinated Ethylene Propylene) is a high-performance fluoroplastic with exceptional properties, including high-temperature resistance, chemical corrosion resistance, and excellent electrical insulation.

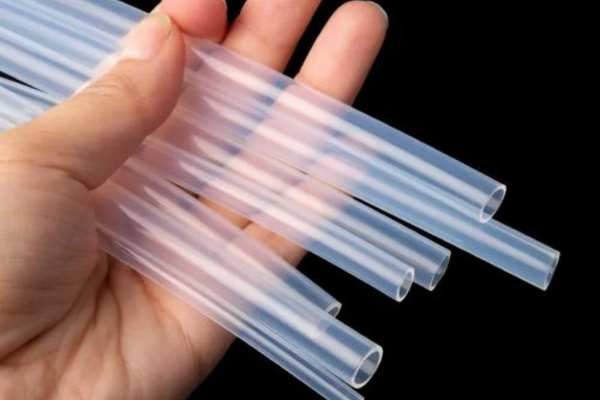

- It’s widely used in high-performance products like wires and cables, pipes, and films.

- Extrusion processing is the core technology for FEP material applications, transforming FEP raw materials into various shaped products.

FEP Material Characteristics and Extrusion Challenges

- FEP’s characteristics present challenges for extrusion processing:

- High melting temperature: Requires extruders with precise temperature control.

- High melt viscosity: Needs sufficient pressure and shear force for smooth extrusion.

- Corrosive gas release: Demands high-quality, corrosion-resistant materials for the extruder.

- Therefore, selecting a suitable FEP extruder is crucial.

Core Technical Requirements of FEP Extruders

- Precise Multi-Zone Temperature Control:

- Use high-precision heating elements and temperature sensors for rapid response and accurate measurement, ensuring melt uniformity.

- Control temperature in areas like the barrel die head, and connecting zones.

- Screw Requirements:

- Material selection: Use corrosion-resistant materials like Hastelloy or 316L stainless steel.

- Structure selection: Twin-screw extruders are highly recommended due to their superior mixing and shearing capabilities.

- L/D ratio: Recommended L/D ratio is between 25:1 and 30:1.

- Pressure Control:

- Stable pressure control ensures uniform melt flow and prevents product defects.

- Include melt pressure sensors, pressure regulating valves, PLC control systems, and pressure display instruments.

- Die Head Design:

- Consider material selection, flow channel design, heating system, structural design, and process control.

- Use corrosion-resistant materials, optimize flow channels, and ensure even temperature distribution.

- implement proper cooling systems, such as water cooling.

- Exhaust System:

- Use corrosion-resistant materials like Hastelloy or 316 stainless steel for parts in contact with FEP.

- Including exhaust ports, vacuum systems, gas treatment devices, and control systems.

- Drive System and Control System:

- Use high-performance, high-precision, and high-reliability components.

- Employ PLC control systems for automation and data recording.

- ensure proper safety measures and alarm systems are in place.

Application Areas of FEP Extruded Products

- Wire and cable: For high-temperature and corrosion-resistant insulation.

- Pipes: For chemically resistant pipes.

- Films: For high-performance films.

- Other industrial applications.

How to Choose a Suitable FEP Extruder

- Consider material properties, product requirements, and application areas.

- Choose professional suppliers for equipment quality and technical support.

Future Outlook of FEP Extrusion Technology

- FEP extrusion technology will become more intelligent and efficient.