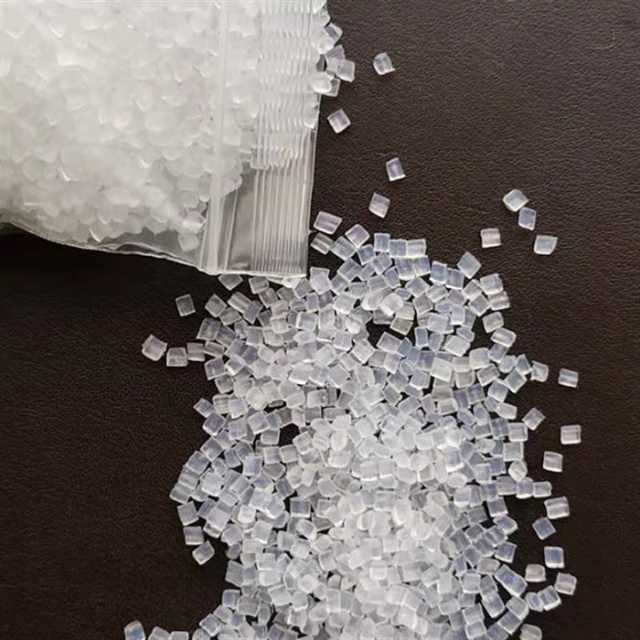

Peflon ETFE (ethylene-tetrafluoroethylene) resin is a a melt-processable copolymer. It has powder, Resin, and Coating forms, It can be customized for any color and is used in various markets, including industry, Energy, Transportation, Aerospace, Electronics, and Medical treatment, such as Wire and cable, tube, film, and Valve linings.

FEP is coated onto other materials like metal or fiberglass for its non-stick and lubricating properties

Typical in cookware, coating for pipes, and various non-stick applications

Impregnating high-temp fabrics with PTFE dispersion: Apply evenly, cure as directed, validate for durability and performance.

Blend PTFE with plastic, process uniformly, test for effective anti-drip properties in manufacturing.

This dispersion exhibits remarkable non-stick attributes, corrosion resistance, and excellent thermal stability. Its low coefficient of friction and exceptional dielectric properties make it an ideal choice in demanding environments.

Recyclable and requires less energy for production compared to other fluoropolymers

No use perfluorooctanic

ETFE Resin offers exceptional tensile strength, providing structural support

20 years weathering capabilities

All Peflon ETFE quality inspections involve rigorous chemical purity testing, weather resistance evaluation, mechanical strength measurement, and optical transparency checks to ensure they meet industry standards and customer requirements.

Peflon ETFE Resins are widely used in oil and natural gas, Oil & Gas, Medical, Food, new energy, construction, water treatment, and other fields, such as Electrical sleeving, Coil forms, Sockets, Connectors, Switches, Fuel hoses, etc.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.