Selecting the right FEP (Fluorinated Ethylene Propylene) Resin is a crucial decision for those involved in the tube manufacturing industry. FEP Resin is renowned for its exceptional properties, making it a popular choice for a wide range of applications. However, choosing the suitable FEP Resin grade can be a daunting task. In this blog, we will simplify the process, helping you make an informed decision.

Understanding FEP Resin

Before diving into grade selection, let’s start with the basics. FEP Resin, a type of fluoropolymer, is known for its remarkable properties. It offers high temperature resistance, excellent chemical compatibility, and outstanding electrical insulation. These characteristics make it ideal for various industries, including tube manufacturing.

Applications in the Tube Industry

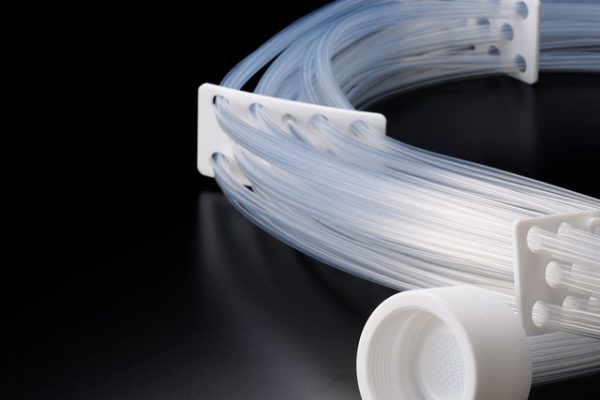

FEP Resin finds extensive use in the tube manufacturing industry due to its unique features. It is often employed in applications where temperature resistance, chemical resistance, and non-stick properties are essential. These tubes are used for transporting various substances, from corrosive chemicals to high-purity fluids.

Factors Influencing Grade Selection

Selecting the right grade for FEP Resin is essential, and it depends on the specific needs of your application. Several factors influence this decision:

- Temperature Resistance: Consider the operating temperature of your application. Different FEP Resin grades have varying temperature limits.

- Chemical Compatibility: FEP Resin is known for its resistance to a wide range of chemicals. However, it’s essential to match the resin’s properties with the specific chemicals in your process.

- Mechanical Properties: Some applications may require specific mechanical attributes like flexibility or stiffness. Choose a grade that aligns with these requirements.

Exploring FEP Resin Grades

FEP Resin comes in various grades, each tailored to meet different industry needs. Let’s explore some of the common grades and their properties:

- Standard FEP Resin: This is the most widely used grade, offering a balanced combination of properties.

- High-Performance FEP Resin: If you need exceptional performance at high temperatures, this grade is a suitable choice.

- Modified FEP Resin: For applications requiring improved chemical resistance, modified FEP Resin might be the answer.

Selecting the Right Grade

To make the best selection, evaluate your application’s specific needs. Take the following steps:

- Identify Requirements: Clearly define your application’s requirements in terms of temperature, chemical exposure, and mechanical properties.

- Match Properties: Compare the properties of FEP Resin grades with your application requirements. Ensure they align.

- Quality and Standards: Choose a grade that complies with industry standards and quality certifications like SHVC, RoHS, and PFAS.

- Supplier Selection: Find a reputable FEP Resin supplier who can provide the grade you need. Consider factors like delivery time, reputation, and certifications.

Cost Considerations

While quality is paramount, cost is also a significant factor. Striking the right balance is crucial. Investing in a higher-grade FEP Resin can lead to long-term cost savings by reducing maintenance and replacements.

Real-World Examples

To illustrate the importance of choosing the right FEP Resin grade, let’s look at a few case studies:

- Case Study 1: A chemical processing plant needed FEP Resin for their corrosive chemical transport tubes. They opted for a high-performance grade to ensure longevity and safety.

- Case Study 2: A food processing company in the UK used standard FEP Resin for their food-grade tubing, ensuring FDA compliance and reliability.company

Conclusion

Choosing the suitable FEP Resin grade for tube manufacturing is a critical decision that impacts the efficiency and safety of your operations. By understanding your application’s specific requirements, evaluating available grades, and selecting a reputable supplier, you can make an informed choice that ensures the success of your tube manufacturing processes.