Peflon is a China-based manufacturer supplying PVDF material to industrial buyers who require technical validation, controlled production, and custom material options. You work directly with the source to reduce qualification risk and support long-term supply planning

Controlled PVDF material batches for qualification and scale-up

FDA, REACH, ROHS Approved

Industrial PVDF material supply with predictable lead times

PVDF material, CAS 24937-79-9, also named polyvinylidene fluoride, is a fluoropolymer used when chemical resistance, processing control, and long-term stability matter in real production environments.

You typically select PVDF material for applications that require resistance to aggressive chemicals, stable performance under heat, and predictable behavior during extrusion, molding, or coating. Compared with higher-temperature fluoropolymers, PVDF material offers a practical balance between durability and processability, which helps reduce manufacturing risk during scale-up.

Peflon supplies PVDF material in industrial forms designed for qualification and repeatable use. You can evaluate PVDF material properties, processing behavior, and batch consistency before committing to volume orders. With controlled production and documentation support, you move from testing to supply with fewer variables and clearer technical alignment.

| Grade | Material Type | MFR (g/10 min) | Key Material Feature | Typical Application |

|---|---|---|---|---|

| PF-8P61 | PVDF Powder | Low | High molecular weight, low flow | Extrusion & structural molded parts |

| PF-8P62 | PVDF Powder | Low–Medium | Balanced flow and mechanical stability | General extrusion & injection molding |

| PF-8P63 | PVDF Powder | Medium | Improved flow for molding | Injection molded components |

| PF-8P64 | PVDF Powder | High | High flow, easier mold filling | High-flow injection products |

| PF-8P02E | PVDF Binder Grade | Medium | Stable viscosity, film-forming binder | Lithium battery electrode binder |

| PF-8P02B | PVDF Binder Grade | Low | High binding strength | High-loading battery electrodes |

| PF-8P04 | PVDF Membrane Grade | Low–Medium | Good solubility, controlled viscosity | PVDF membranes & filtration |

| PF-8P03 | PVDF Coating Grade | Medium | Fine particle size for coating | Fluorocarbon coatings |

| PF-8P11 | PVDF Coating Grade | 0.5–2.0 | High UV & chemical resistance | Architectural & industrial fluorocarbon coatings |

Peflon PVDF material is available in multiple industrial forms to help you match processing methods, qualification needs, and end-use conditions. By selecting the right PVDF material category, you can reduce trial time, control production variables, and transition more quickly from validation to a stable supply. Explore each PVDF material category below to find the best fit for your application and sourcing plan.

PVDF resin is supplied in pellet or granule form for thermoplastic processing. You typically choose this PVDF material category when your production involves extrusion or injection molding and requires dimensional stability across batches.

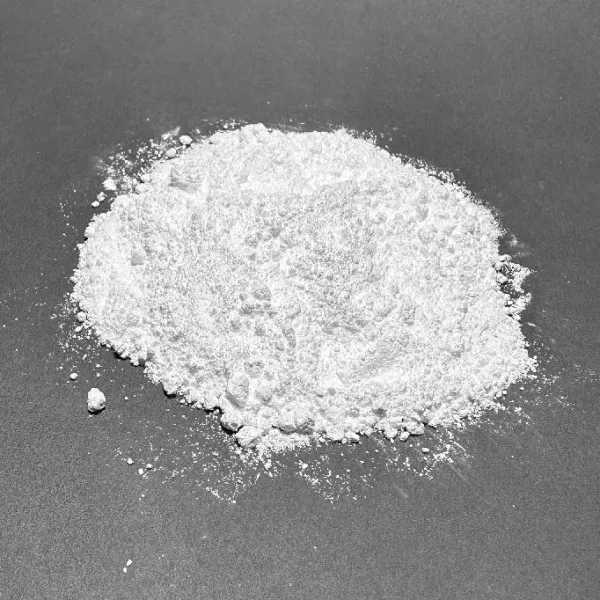

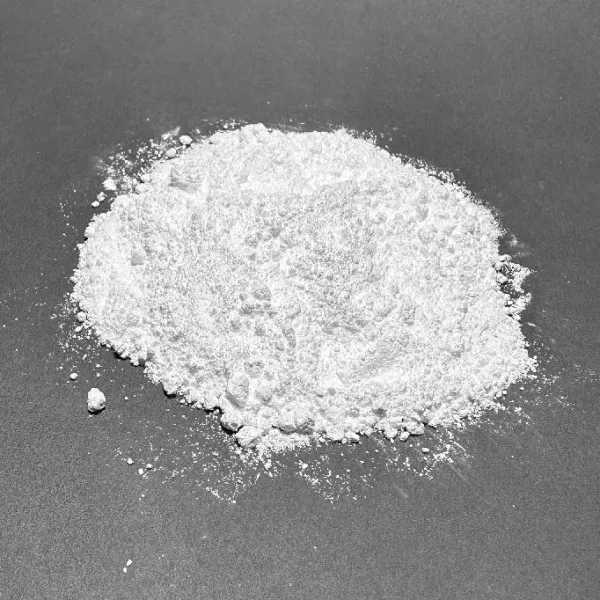

PVDF powder material is selected when uniform dispersion or fine material control is required. This PVDF material category is commonly evaluated in Fluorocarbon coatings systems, membrane formation, and binder-based processes.

PVDF coating-grade material is used when surface protection and long-term exposure resistance are key requirements. You evaluate this PVDF material category based on coating method, substrate compatibility, and service environment.

PVDF membrane-grade material is evaluated for applications requiring durability and stable membrane performance. This PVDF material category is typically reviewed by technical and QA teams during process qualification.

PVDF material is commonly specified in chemical processing environments where exposure to aggressive media is expected. You typically evaluate PVDF material for systems that require maintaining integrity over extended service periods.

Peflon PVDF material is not positioned as a universal solution for every application. If your process is unstable or your validation criteria are unclear, switching suppliers alone will not fix the problem. Our role is to support buyers who already understand their requirements and need a PVDF material partner that respects process discipline, documentation, and repeatability.

What differentiates Peflon is not marketing claims, but how PVDF material is prepared, verified, and supported during qualification and scale-up.

PVDF material performance starts with raw material control. Without stable inputs, downstream testing becomes meaningless. Peflon manages PVDF material production with defined raw material specifications to reduce variability before qualification even begins.

Defined raw material acceptance criteria

Reduced formulation drift during scale-up

Fewer re-tests caused by upstream variation

Peflon PVDF material judged by repeatability, not by single data points. Peflon supports PVDF material evaluation with batch-level testing and documentation to help you confirm consistency over time, not just on first samples.

Avoids “sample OK, bulk fails” scenarios

Supports QA and technical audits

Aligns material data with real production behavior

Changing PVDF material suppliers mid-production is costly. Peflon approaches PVDF material supply with long-term planning to support buyers who value continuity over short-term pricing.

Predictable supply windows

Reduced re-qualification risk

Fewer disruptions during ongoing production

For applications requiring higher continuous temperature resistance, PTFE materials are commonly reviewed. When melt processing flexibility or transparency is important, FEP or PFA materials may be evaluated during material selection. Each material addresses a different set of design constraints and validation requirements.

Not always. PVDF material offers easier processing than PTFE, but it operates within a lower temperature range. You should evaluate PVDF material as an alternative only after confirming thermal limits and service conditions for your specific product.

PVDF material selection depends on how the product is made. Resin is typically reviewed for molded or extruded parts, powder for binders or coatings, and membrane-grade PVDF material for filtration products. Form selection should follow your process, not the other way around.

Yes. Even when specifications look similar, PVDF material should be re-validated when suppliers or grades change. Batch-to-batch consistency and processing behavior can vary and directly affect product performance.

PVDF is premium-grade for demanding applications, while PVC is a cost-effective choice for general-purpose uses with moderate conditions.

PVDF is premium-grade for demanding applications, while PVC is a cost-effective choice for general-purpose uses with moderate conditions.

PP is widely used for general-purpose chemical resistance, while PVDF material is selected for harsher environments. PVDF material performs better under higher temperatures and aggressive media, but PP may be sufficient for less demanding applications.

PP is widely used for general-purpose chemical resistance, while PVDF material is selected for harsher environments. PVDF material performs better under higher temperatures and aggressive media, but PP may be sufficient for less demanding applications.

PVDF material price reflects its fluoropolymer chemistry, controlled production, and performance range. While PVDF material costs more than PVC or PP, it is typically evaluated for applications where longer service life and reduced failure risk justify the investment.

Technical support for PVDF raw material is focused on material understanding, not process control. Peflon supports buyers by providing clear information on PVDF material properties, batch consistency, and suitability for specific application types. This helps you reduce uncertainty during qualification and sourcing.

Wether you are, a manufacturer or distributor, contact us for a Free sample or solution, Peflon provides one-stop technical solution.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.