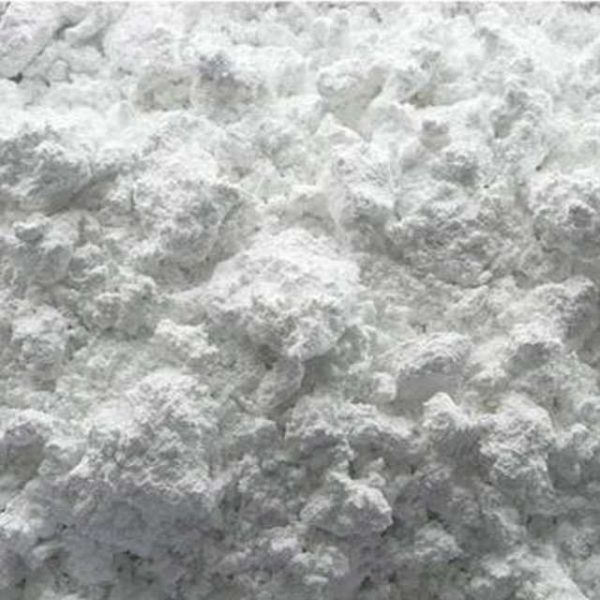

Peflon Glass-filled PTFE is a reinforced PTFE material. It is pure PTFE with glass fibers added as fillers to improve the mechanical properties of the material.

Selection of the appropriate percentage of glass fiber filler usually depends on the application requirements, and different glass fiber contents can affect the material’s performance.

Peflon Glass-filled PTFE is used in various applications due to its excellent mechanical strength, wear resistance, low coefficient of friction, and chemical inertness.

Peflon Glass-filled PTFE with great properties.

Whether you’re interested in our products, need a quote, or have any other requirements, we look forward to hearing from you. And you will get a perfact solution.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.