Reliable PFA raw material for extrusion, coating, and semiconductor applications – custom grades, fast delivery, and consistent purity guaranteed by Peflon.

PFA (Perfluoroalkoxy) polymer is a family of Teflon and is a tough, flexible fluoropolymer. It has almost the same properties as PTFE; the difference is that PFA resin can be melted, whereas PTFE cannot. With exceptional chemical resistance, high-temperature tolerance, and excellent electrical insulation properties, PFA stands as a top choice for demanding applications.

PFA resin is used in industries such as chemical processing, semiconductor manufacturing, wire and cable, Tube, Film, and LED cover production, among others. Its versatility and reliability make it a cornerstone of high-performance applications.

As a professional PFA material supplier, Peflon offers a wide range of raw material forms for different industrial processes. From high-purity resin pellets to extrusion-grade tubing, our products ensure excellent chemical resistance, thermal stability, and process consistency. Each grade of PFA material is produced under ISO-certified systems.

Contact us for material selection or customized grades.

PFA resin is the foundation of our fluoropolymer portfolio. It features outstanding purity, melt-processability, and excellent stress-crack resistance. Peflon’s PFA resin material is suitable for extrusion, injection molding. Available in various melt-flow indices, it ensures smooth processing for tubing, film, and wire insulation production.

Our high-purity PFA material is specifically designed for the semiconductor and chemical industries, where ultra-clean standards are required. It meets SEMI specifications and ensures contamination-free processing. For cleanroom environments and precision extrusion.

PFA Micro Powder provides strong adhesion to metals and glass, forming a durable anti-corrosive layer. It is widely used in reactors, valves, and chemical storage tanks that require long-term resistance to strong acids and solvents. Peflon’s coating-grade PFA ensures uniform film thickness and high surface clarity.

PFA dispersion is a water-based form of PFA polymer designed for coating and impregnation. It provides a uniform film with outstanding chemical resistance and smooth surface finish. Peflon’s PFA dispersion can be applied to metals, glass, and carbon surfaces to create anti-stick, corrosion-resistant coatings. It’s suitable for spray, dip, or flow coating in industrial production.

PFA resins excel in the chemical processing, semiconductor, medical, and electronic industries. Their superior chemical resistance, high-temperature stability, and purity make them ideal for critical applications. Used in pipes, wires, and labware, PFA ensures reliability in harsh environments.

Choosing the right PFA material supplier is critical to ensure stable production, consistent quality, and cost efficiency. Peflon focuses exclusively on industrial-grade and high-purity PFA raw materials, offering a combination of certified manufacturing, strict quality control, and tailored OEM solutions. Our customers rely on us for long-term partnership, transparent processes, and dependable delivery worldwide.

At Peflon, we control every stage of polymerization and compounding to guarantee consistency in every batch. Our PFA resin and dispersion products are manufactured under ISO 9001 and ISO 14001 standards, ensuring steady melt flow, low impurity levels, and excellent reproducibility across orders.

All PFA material batches are tested in-house and by third-party labs for chemical, mechanical, and purity parameters. Each product meets or exceeds ASTM D3307 and SEMI F-57 specifications to ensure safety and reliability for critical industrial use.

ICP-MS analysis for metal and ion extractables

SEMI-compliant high-purity verification

Visual and melt flow inspection per batch

Full documentation and COA provided upon delivery

Every industry has unique processing needs. Peflon R&D teams with custom PFA polymer formulations, melt flow adjustments, and packing solutions. Our technical experts help you optimize extrusion, molding, and coating performance to achieve higher efficiency and lower waste.

OEM packaging and private labeling available

On-site or remote technical assistance

Fast response for sample evaluation and quote

Peflon also provides PTFE, FEP, ETFE, and PVDF raw materials. Each polymer offers unique performance for different processing needs.

PFA resin processing requires precise control due to its high melt viscosity. Techniques like extrusion, injection molding, and compression molding are used. Key factors include temperature management and avoiding degradation. Proper processing ensures PFA’s excellent properties are retained in the final product.

Compression molding of PFA material is ideal for producing thick and complex parts with excellent dimensional stability. The process uses heat and pressure to shape preforms into sheets, rods, or valve components. It’s widely applied in chemical, electrical, and semiconductor equipment manufacturing.

PFA injection molding allows precise and repeatable production of complex shapes. It is suitable for fabricating fittings, pump parts, and valve seats. The melt-processable PFA polymer provides excellent surface finish and chemical resistance for critical fluid handling systems.

Transfer molding of PFA resin is used for small, detailed parts requiring uniform density and smooth surfaces. This method is common in producing O-rings, seals, and precision laboratory components that must resist chemicals and heat.

Electrostatic coating spray PFA Micpowder onto metal or glass surfaces, creating seamless, non-stick, and corrosion-resistant layers. It is used for coating chemical tanks, stirrers, reactors, and molds that require high-temperature and chemical protection.

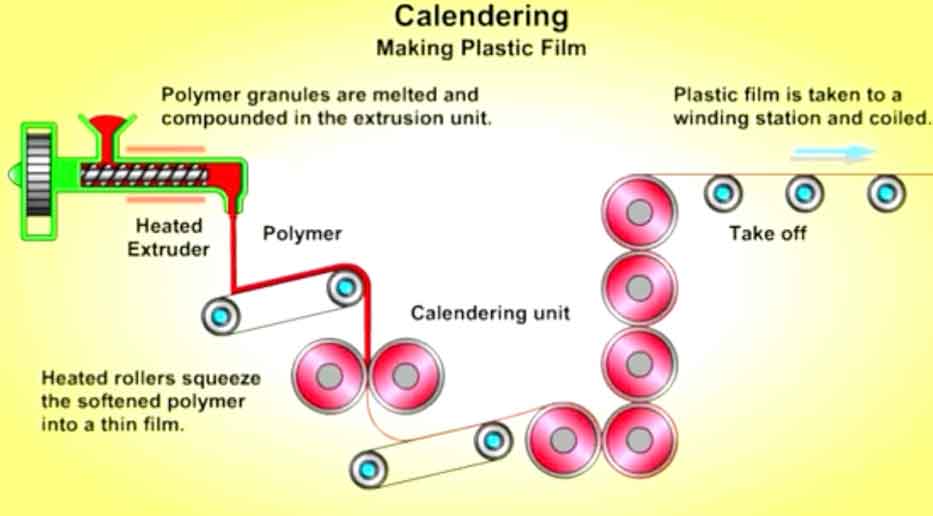

Calendering processes PFA material through heated rollers to produce thin, uniform films or laminated sheets. This method is used for PFA film, composite layers, and protective coatings, ensuring optical clarity and smooth surface finish.

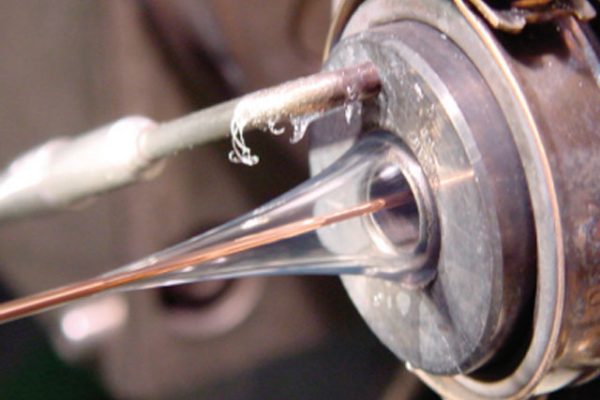

Melt extrusion is the most common method for shaping PFA polymer into tubing, wire coatings, and films. The molten material flows through a die, creating continuous profiles with uniform thickness, flexibility, and transparen

At Peflon, we go beyond supplying PFA material — we provide complete technical support for your production and R&D projects. Our engineers help you select the right PFA resin grade, optimize extrusion and coating parameters, and troubleshoot processing challenges. We also offer melt flow testing, purity analysis, and performance comparison for PFA polymer versus PTFE or FEP. Whether you need help with new product development or quality validation, Peflon’s technical team ensures your process runs efficiently and consistently.

Peflon specializes in providing industrial and high-purity PFA resin for extrusion, coating, and molding applications. Whether you’re a distributor, OEM factory, or R&D engineer, our team is ready to support your project with technical expertise and fast delivery. Simply fill out the inquiry form, and one of our specialists will respond within 24 hours with detailed information, data sheets, and quotation options. Partner with Peflon to ensure a stable supply of premium PFA polymer for your production.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.