Peflon Teflon PTFE Sheet is a teflon plates made of polytetrafluoroethylene (PTFE) material.PTFE Sheet is commonly used for sealing, gasket, insulating, lining, and other applications, especially in the chemical, food, electronic, mechanical,l and other industries have been widely used.

Delivery time within 10 work days, we can meet the different needs of different customers.

We are a trustworthy PTFE sheet manufacturer, we have different sizes of PTFE sheets. If you want to buy PTFE sheet, please choose us!

Peflon PTFE sheets always be produced by Molding, Extruded, and skilled processing methods.

Processing: Teflon board manufactured by the molding process.

Applications: Used for seals, gaskets, pipe linings, etc. that require high mechanical strength, temperature and corrosion resistance.

Advantages: More stable molding, and usually have higher physical properties, with better dimensional stability, suitable for more stringent industrial environment.

Processing: PTFE film made by extrusion process.

Applications: seals, insulation, electrical insulation, lining materials, etc.

Advantages: Simple production process, low cost, usually thin and low density, suitable for general industrial applications.

Characteristics: Skived Teflon PTFE sheet is a type of film that is cut from large pieces of PTFE (polytetrafluoroethylene) by a mechanical turning process.

Advantages: Chemical stability, high and low temperature resistance, mechanical strength and electrical insulation properties.

Applications: Chemical, electronics, medical, food, aerospace and other fields.

Filled PTFE Sheet material

Peflon add other fillers to the pure PTFE material to enhance the properties of the material, this is Filled PTFE Sheet.

Made of pure polytetrafluoroethylene (PTFE) material without any additives or recycled materials.

Advantages: With no added fillers or recycled materials, Virgin PTFE offers the highest purity and consistency.

Applications: Used for linings, gaskets and seals and as an insulating material.

PTFE with glass fibers (typically 10% to 30%)

Advantages: Enhances the compressive strength and abrasion resistance of PTFE, suitable for high loads and applications requiring high strength.

Applications: Used in the manufacture of high-strength seals, gaskets, wear-resistant parts, mechanical slides, etc.

A black PTFE sheet add carbon powder PTFE.

Advantages: Carbon-filled PTFE has enhanced wear resistance, good mechanical properties, and electrical conductivity for higher-load applications.

Applications: Suitable for high-pressure seals, pump seals, sliding parts, etc.

Graphite powder is added to PTFE to increase the material’s thermal conductivity, abrasion resistance and self-lubrication.

Advantages: Graphite-reinforced PTFE sheet has better friction, wear and heat resistance and a lower coefficient of friction.

Applications: Commonly used in high-temperature, low friction applications such as bearings, sliders, seals, pump parts, etc.

Characteristics: Highly flexible and compressible through a special process.

Advantages: Expanded PTFE has low density and good sealing performance, suitable for irregularly shaped seals.

Applications: Used for irregular joints, flange seals, low pressure seals, etc.

Peflon Teflon PTFE sheets can be classified into the following categories according to their thickness:

Thickness: 2mm – 10 mm

Characteristics: Medium thickness provides increased compressive strength for medium load and compression applications.

Applications: Sealing gaskets, liners and sliding parts

Thickness: 0.5 mm – 2 mm

Characteristics: Good flexibility and processability for applications requiring high-precision cutting.

Applications: Used for insulating parts of high-frequency electrical equipment and sealing of small devices or valves.

Thickness: 10 mm – 50 mm or thicker

Characteristics: With very high compressive strength, it maintains the chemical stability and high temperature resistance of PTFE and is able to work in extreme environments.

Applications: Large Equipment Seals.

PTFE Sheet is widely used in many industries and fields due to its excellent chemical resistance, low coefficient of friction, high and low-temperature resistance and good electrical insulation properties.

PTFE sheet can be divided into four categories: Type 1 is mainly used for gaskets, Type 2 is used for lining, and lining parts, Type 3 is used for corrosive media in the diaphragm, and the fourth category is mainly used for electrical insulation.

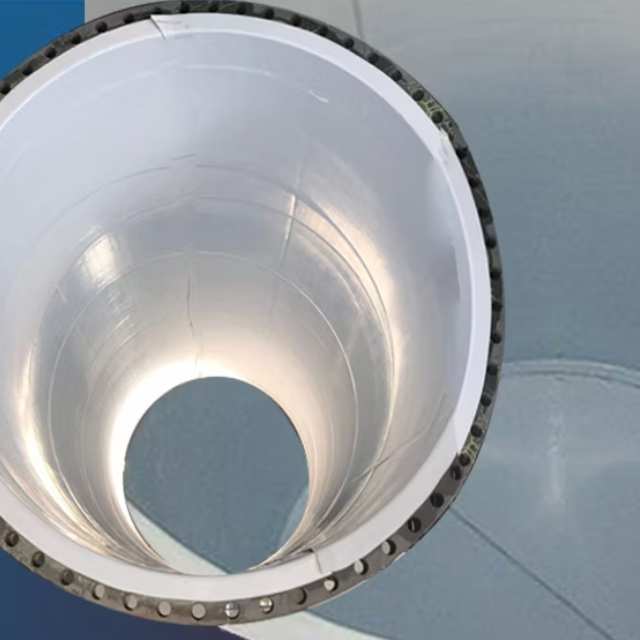

PTFE sheets are used for lining chemical reactors, tanks, pipelines and other equipment.

PTFE sheet has very excellent electrical insulation properties, widely used in high-frequency electronic components in the insulation materials.

PTFE sheets are widely processed into various kinds of sealing gaskets, O-rings, flange gaskets and so on.

For use in corrosive media.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.