Bulk thv polymer fast production slots.

Are you looking to bulk buy thv fluoropolymer

You get Peflon thv material based on the TFE-HFP-VDF terpolymer, delivering clarity, flexibility, and a strong fuel / chemical barrier. you can pick pellet, powder or thv dispersion forms to suit extrusion, casting, coating or lamination. Our factory issues COA, process guides, and supports your validation with documentation. We operate dedicated lines for thv fluoropolymer from China, producing stable batches to match your specs. Use it in fuel hoses, cleanroom tubing, cable jackets, safety films — we help you lock MOQ, lead time, and trial allotment now

Choose from Peflon thv polymer categories designed for extrusion, molding, coating, and lamination. Our thv fluoropolymer runs at lower melt temperatures with high clarity and strong chemical resistance. Whether you need thv resin, thv powder, or thv dispersion, we tailor supply to your process. Request a quote to lock MOQ and delivery time for your next project.

THV resin pellets for extrusion or injection molding. These grades combine flexibility, transparency, and fuel-barrier performance. Use them for multilayer hoses, tubes, or cable jackets.

Key benefits: consistent melt flow, easy co-extrusion with PE or TPE, and clean color stability.

THV polymer powder offers smooth dispersion and thin-film control. Ideal for casting clear laminates or coating glass and composite sheets where optical quality matters.

Key benefits: tight particle-size distribution, low haze, strong bonding to base layers.

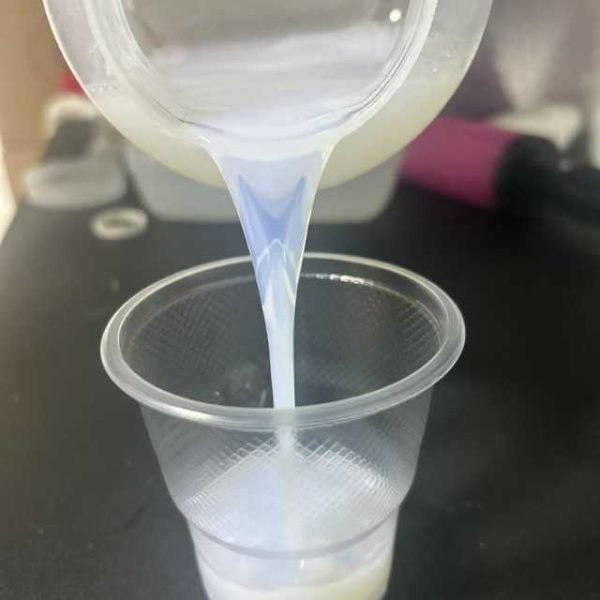

Our THV dispersion makes coating and dipping easy for multilayer hoses, membranes, or wires. It delivers uniform thickness, fast drying, and smooth surface finish.

Key benefits: Stable solid content, long pot life, excellent adhesion on PE or TPE.

When you choose Peflon THV polymer, you secure a dependable material source with full technical and logistics support. Our THV fluoropolymer production is verified by internal QC and traceable lots, giving you stable quality for every shipment. Whether you’re scaling up extrusion, lamination, or coating, we help you validate faster and keep your lines running without interruption.

Contact us for trial grades and volume planning.

Your THV fluoropolymer supply matters. HCT sources certified raw materials and manages lot traceability to guarantee consistent performance.

Real-time production monitoring for each run

Every batch of THV polymer is tested for haze, melt flow, and permeability before shipment. You receive a complete CoA and data sheet for regulatory confidence

Optical clarity and haze tests for film grades

Melt flow index and density checks per lot

Fuel barrier and dielectric strength reports

We help your engineers fine-tune extrusion, coating, or molding parameters using THV resin. Utilize processing windows and bonding guides to minimize waste and reduce setup time.

Start-up temperature and pressure profiles

Bonding charts for PE, PP, and TPE layers

Troubleshooting guides for multilayer structures

As global demand changes, Peflon keeps your THV material supply stable with planned stock and flexible shipment options.

Safety stock for key THV grades

Predictable lead times and batch reservation

Shipping from multiple bonded warehouses

If you handle multilayer hoses, films, or tubing, you may also need complementary materials beyond thv polymer. Peflon supplies a full range of fluoropolymers like PVDF, FEP, and ETFE, each designed to balance clarity, toughness, and chemical resistance. By combining THV fluoropolymer with these materials, you can fine-tune bonding layers, fuel resistance, and optical stability for different applications. Explore our related products to find the perfect match for your extrusion or coating line, and request a sample to test compatibility before making a bulk purchase.

Stay ahead in process optimization with our thv polymer technical insights. Peflon’s engineering team shares real production data on extrusion profiles, film casting, and bonding techniques for thv fluoropolymer applications. You’ll learn how to fine-tune melt flow, achieve clear lamination, and reduce start-up waste. Each blog post includes setup tips, QC checklists, and troubleshooting notes based on real factory runs. Visit our Technical Support Center to download guides and connect with process specialists for your next project.

Ready to source thv polymer in bulk? Tell us your project details. Our Peflon team will match the right thv fluoropolymer grade and confirm MOQ, pricing, and delivery schedule.

Fill out the form on the right to receive a detailed quotation within 24 hours. Whether you’re planning extrusion, lamination, or coating runs, our engineers are ready to support you from sampling to mass production.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.