Utilizing paste-extrusion techniques, the PTFE fine powders can form continuous-length PTFE items like tubes, tapes, and membranes. Peflon™ PTFE fine powders stand as the fluoropolymer of choice across various applications, notably in creating breathable hydrophobic membranes, aerospace/automotive hoses, and high-performance wires and cables.”

Exceptional Thermal Stability: PTFE fine powders exhibit unparalleled resistance to high temperatures, ensuring reliability in extreme thermal conditions.

Low Coefficient of Friction: With inherent non-stick properties, these powders reduce friction, enhancing operational efficiency and equipment longevity.

Chemical Inertness: Resistant to a wide array of chemicals, PTFE fine powders offer superior corrosion resistance, making them ideal for harsh environments and chemical applications.

Outstanding Dielectric Properties: These powders serve as excellent electrical insulators, ensuring safety and reliability in electrical applications

FEP (Fluorinated Ethylene Propylene) resins are highly versatile materials with a wide range of applications across various industries.

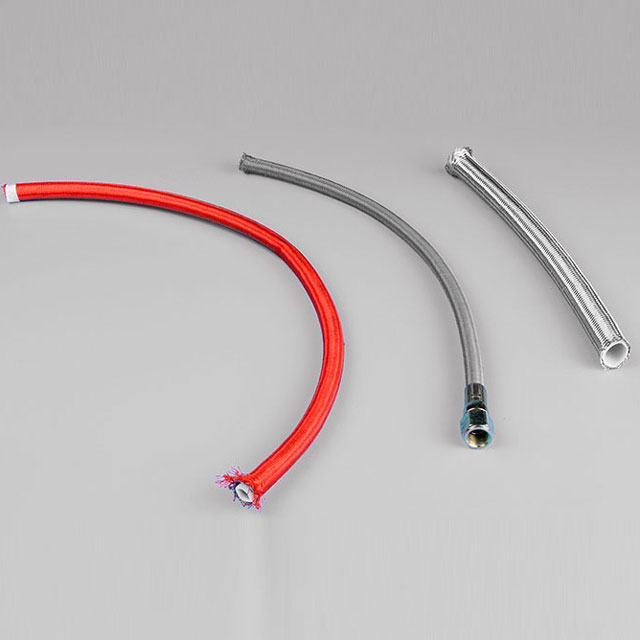

PTFE fine powders are utilized in manufacturing continuous-length tubes and pipes, ensuring excellent resistance to high temperatures and chemicals.

Mix PTFE Fine Powder, extrude into liner shape. Ideal for lining pipes in chemical, industrial, and oil/gas sectors for corrosion resistance.

PTFE Electrical Tape offers exceptional insulation and heat resistance for electrical wiring applications. Sleeving, with its durable PTFE construction, safeguards wires and cables from environmental factors.

Blend PTFE Fine Powder with additives and extrude into tubing. Stretch tubing for enhanced properties and cool to solidify. Widely used in medical, chemical, and electronics industries for tubing purposes.

PTFE Breathable Membranes, renowned for their exceptional breathability and waterproof properties, find applications in various industries: Outdoor Apparel, Medical Textiles, Building Material, Industrial Filtration.

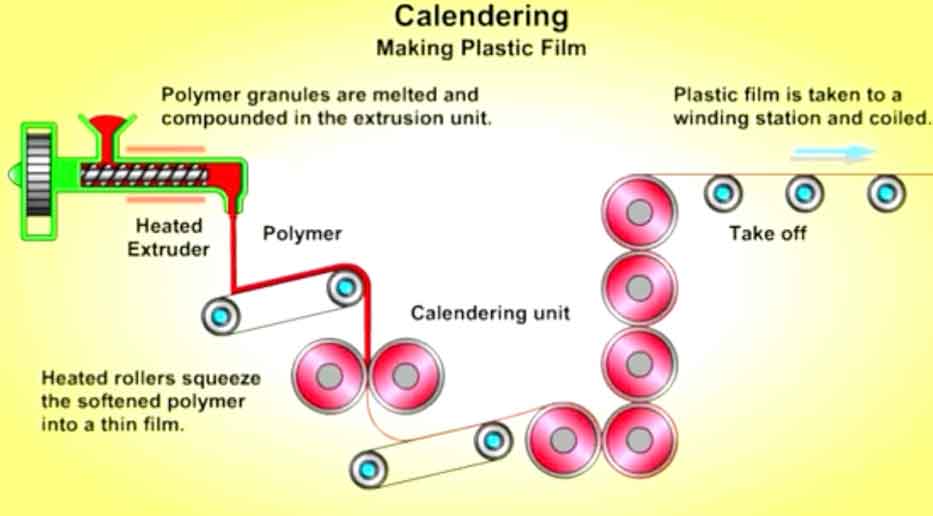

Blend PTFE Fine Powder, calender into tape. Widely used for sealing pipe threads, joints, and connections in plumbing and industrial applications.

PTFE (Polytetrafluoroethylene) skived membranes are thin, versatile materials used across diverse industries for their unique properties and applications.

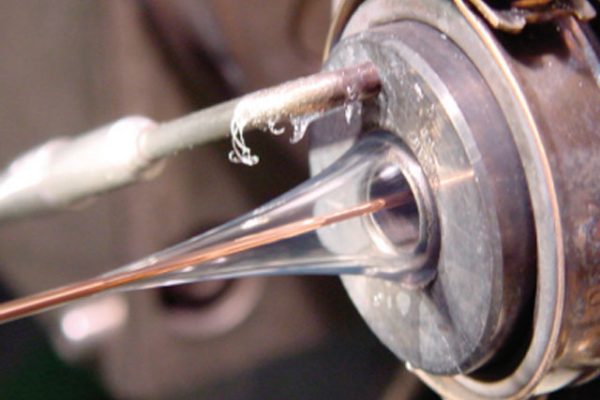

PTFE Coaxial Cables feature a central conductor, insulating dielectric, shielding, and protective jacket, utilizing PTFE for enhanced electrical performance.

Fluorinated Ethylene Propylene (FEP) resin, renowned for its versatile properties, can be processed through various methods to create an array of products and coatings. Here are the primary processing techniques used for FEP resin:

Compression Molding, Injection Molding, Hot Forming, Coating, Calendering, Melt Extrusion etc.

PTFE Virgin powder is placed into a mold and compressed to shape it.

Suitable for complex shapes or larger-sized FEP products

Molten FEP is injected into molds, cooled, and solidified to produce various parts.

Ideal for items like valves, connectors, and components.

FEP sheets or stock material are heated and manually or mechanically formed into desired shapes.

Used for small batch production or unique shapes.

FEP is coated onto other materials like metal or fiberglass for its non-stick and lubricating properties

Typical in cookware, coating for pipes, and various non-stick applications

Molten FEP resin is passed through roller equipment to form thin films or sheets.

Commonly used to produce FEP films, sheets, and expanded sheets

FEP pellets are heated to a molten state and then extruded into continuous shapes, such as rods or tubes

Widely used for manufacturing wire and cable insulation, pipes, films, and rods.

If you source PTFE Fine Powder, we also provide other Teflon Material.

Not always. PVDF material offers easier processing than PTFE, but it operates within a lower temperature range. You should evaluate PVDF material as an alternative only after confirming thermal limits and service conditions for your specific product.

PVDF material selection depends on how the product is made. Resin is typically reviewed for molded or extruded parts, powder for binders or coatings, and membrane-grade PVDF material for filtration products. Form selection should follow your process, not the other way around.

Yes. Even when specifications look similar, PVDF material should be re-validated when suppliers or grades change. Batch-to-batch consistency and processing behavior can vary and directly affect product performance.

PVDF is premium-grade for demanding applications, while PVC is a cost-effective choice for general-purpose uses with moderate conditions.

PVDF is premium-grade for demanding applications, while PVC is a cost-effective choice for general-purpose uses with moderate conditions.

PP is widely used for general-purpose chemical resistance, while PVDF material is selected for harsher environments. PVDF material performs better under higher temperatures and aggressive media, but PP may be sufficient for less demanding applications.

PP is widely used for general-purpose chemical resistance, while PVDF material is selected for harsher environments. PVDF material performs better under higher temperatures and aggressive media, but PP may be sufficient for less demanding applications.

PVDF material price reflects its fluoropolymer chemistry, controlled production, and performance range. While PVDF material costs more than PVC or PP, it is typically evaluated for applications where longer service life and reduced failure risk justify the investment.

If you are ready to source PTFE Fine Powder for cable, tubes, Fiber, and yarn, our team is here to help. Please provide us with your request, and we will prepare samples, datasheets, and a clear quotation.

Fill in the form on the right, and our team will contact you shortly.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.