Partner with Peflon to source high-performance fluoropolymer materials for coatings, films, and tubing. We deliver consistent quality, fast shipment, and full technical documentation to support your production and R&D needs.

Stable bulk supply for global production

ISO-certified quality and traceable batches

Fluoropolymer, including PTFE, PFA, FEP, PVDF, etc., is a class of high-performance polymers defined by strong carbon–fluorine bonds that deliver superb chemical resistance, thermal stability, and nonstick surface.

As a buyer or R&D engineer, you expect raw material you can trust. At Peflon, we produce fluoropolymer grades that meet ISO and ASTM benchmarks, provide full batch traceability, and support custom formulations for coatings, tubing, films, and compounding.

With decades of fluoropolymer production experience, Peflon runs multiple production lines, holds quality certifications, and offers one-stop supply from raw polymer to coating systems. Our materials serve key sectors like photovoltaics, chemical processing, semiconductors, and architectural finishes.

Get in touch today to request samples or a quote for your next fluoropolymer procurement.

Peflon offers a wide range of fluoropolymer materials to meet diverse industrial demands. From PTFE and PVDF to amorphous and high-temperature grades, each fluoropolymer is engineered to provide unique performance for coatings, tubing, films, and molded parts. Explore our comprehensive category list below to find the ideal solution for your project.

PTFE fluoropolymer resin is valued for its excellent nonstick surface, chemical inertness, and dielectric properties. It is ideal for sealing components, chemical tank linings, and insulation layers.

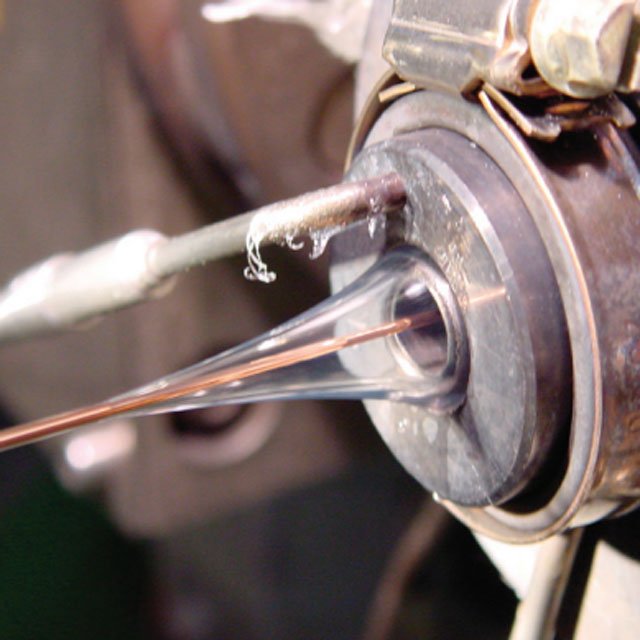

PFA fluoropolymer offers high purity, smooth surface, and melt-processability, making it perfect for semiconductor fluid handling and transparent tubing applications.

FEP fluoropolymer combines low friction and high clarity. It’s used in wire insulation, film extrusion, and heat-shrink tubing for electrical and chemical systems.

PVDF fluoropolymer is known for outstanding UV and weather resistance. It’s widely used in architectural coatings, battery binders, and chemical pipes.

ETFE and ECTFE fluoropolymers provide superior impact resistance and durability under harsh environments. They are commonly used in cable jacketing, protective films, and chemical transport systems.

Amorphous fluoropolymers feature transparency, low refractive index, and high chemical stability. They’re perfect for optical films, coatings, and precision electronics.

THV fluoropolymer provides flexibility and easy processing for coatings, films, and 3D printing applications, balancing clarity and chemical resistance.

Our fluoropolymer additives and dispersions improve processability, surface smoothness, and anti-stick performance in thermoplastics and coatings.

Peflon fluoropolymer products support multiple industrial processing techniques to fit different production lines:

Melt Extrusion: For tubing, cable insulation, and films

Compression & Transfer Molding: For sheets, seals, and rods

Electrostatic Coating / Spray: For anti-corrosion coatings

Calendering: For uniform thin film production

Dispersion Coating: For nonstick and high-purity surfaces

Compare key properties and applications of PTFE, PFA, FEP, ETFE, ECTFE (Halar®), PVDF (Kynar®), THV, CYTOP/Teflon™ AF, and ECA high-temperature fluoropolymer materials.

| Property / Material | PTFE | PFA | FEP | ETFE | ECTFE | PVDF | THV | CYTOP/AF | ECA |

|---|---|---|---|---|---|---|---|---|---|

| Melt Processable | No | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Max Continuous Use Temp (°C) | 260 | 260 | 200 | 150 | 150 | 150 | 140 | 200 | 300+ |

| Melting Point (°C) | 327 | 305 | 260 | 270 | 240 | 175 | 130 | — (amorphous) | 340 |

| Tensile Strength (MPa) | 21–35 | 22–30 | 20–30 | 40–50 | 45–55 | 40–50 | 25–35 | 60–80 | 30–40 |

| Elongation at Break (%) | 200–400 | ≈300 | ≈300 | ≈200 | ≈200 | 50–200 | ≈300 | ≈100 | ≈150 |

| Dielectric Constant (1 MHz) | 2.1 | 2.1 | 2.1 | 2.6 | 2.6 | ~8.0 | ~7.5 | ~2.0 | ~2.2 |

| Chemical Resistance | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★★★ |

| Transparency | Opaque | Semi-Clear | Clear | Semi-Clear | Semi-Clear | Translucent | Clear | Fully Transparent | Semi-Clear |

| Flame Rating (UL 94) | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 |

| Weather / UV Resistance | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★★★ |

| Flexibility | ★★☆☆☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★★★ | ★★★☆☆ | ★★★☆☆ |

| Processability (Ease) | ★☆☆☆☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★★★ | ★★★★★ | ★★★☆☆ | ★★★☆☆ |

| Moisture Absorption (%) | <0.01 | <0.01 | <0.01 | 0.03 | 0.05 | 0.03 | 0.05 | 0.01 | 0.01 |

| Key Applications | Seals/Gaskets Insulation | Semi Tubing Wire Coating | Films Heat-shrink | Cable Jacket Films | Tank Lining Chem Piping | Coatings Battery Binder | Flexible Coat 3D Printing | Optical Film Sensors | Hi-Temp Cable Aerospace |

| Typical Form | Powder | Pellets/Disp. | Pellets/Disp. | Pellets | Pellets | Pellets/Powder | Pellets/Disp. | Solution | Pellets |

fluoropolymer materials are trusted by engineers and manufacturers across multiple industries. With exceptional resistance to heat, corrosion, and weathering, they enable reliable performance in demanding production environments. Whether you are designing coatings, tubing, or electronic components, our fluoropolymers help your products last longer and perform better.

Fluoropolymer materials resist aggressive chemicals and acids, making them ideal for tank linings, pipes, and seals in chemical plants. Peflon supplies various grades suited for corrosion-resistant equipment manufacturing.

PCTFE seals protect sensitive items like electronics, solar panels, and screens from moisture.

There are many solar panel suppliers, such as HBOWA, which is a top brand in China

PVDF and other fluoropolymer coatings from Peflon deliver long-term UV protection, color retention, and anti-corrosion performance for building façades and metal panels.

Fluoropolymer insulation provides superior electrical strength, flame resistance, and flexibility for data cables, aerospace wiring, and EV power systems.

Our fluoropolymers are biocompatible, chemically inert, and easy to sterilize—ideal for tubing, catheters, and lab equipment used in healthcare environments.

PVDF and ECTFE grades support next-generation energy storage by offering dielectric strength and electrolyte resistance, perfect for lithium-ion batteries and solar equipment.

Tell us your project details. Our Peflon team will match the right fluoropolymer grade and confirm MOQ, pricing, and delivery schedule.

Fill out the form on the right to receive a detailed quotation within 24 hours. Whether you’re planning extrusion, lamination, or coating runs, our engineers are ready to support you from sampling to mass production.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.