Peflon is a China-based manufacturer supplying custom pre-sintered PTFE materials for industrial molding and extrusion users. You work directly with a production-focused supplier, not a trading layer, to evaluate grades, request samples, and secure long-term supply

Custom pre-sintered PTFE grades for your process

Direct China manufacturer, no trading intermediaries

Sample-ready supply for industrial evaluation

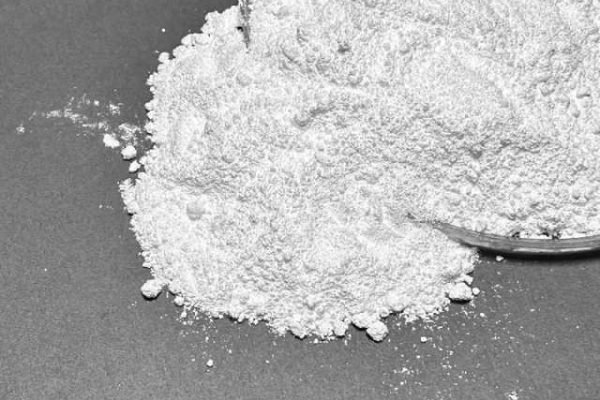

Pre-sintered PTFE, also named partially sintered PTFE material, refers to PTFE resin that has undergone controlled thermal treatment before final sintering. You typically evaluate pre-sintered PTFE when your production relies on cold forming steps, such as compression molding or ram extrusion, where material handling and shape retention before full sintering are critical.

Processing of PTFE pre-sintered compounds includes dry pressing, hot press molding, injection molding, sintering and post-processing to ensure excellent performance in a variety of applications.

Compression molding of PTFE enables the creation of reliable, high-performance components used across various industries for their exceptional properties and reliability in demanding applications.

High-pressure shaping of PTFE resin in molds, ensuring precise parts with exceptional chemical resistance and durability.

Ram extrusion is a process for molding PTFE. The powder is first loaded into a mold and pressed, then heated and extruded into shape, cooled and demolded. Finally, it is cut and quality inspected. This process allows for the manufacture of high performance parts with complex shapes.

PTFE Pre-sintered Resin are used in a wide range of applications in the seals, bearings, electrical insulation, chemical processing equipment and food and pharmaceutical industries.

For sealing of reactors, pipes and valves

Improved durability and performance as a bearing material in automotive components

As a key sealing element in pumps, compressors and mechanical seals

For lining and sealing of chemical reactors to prevent chemical leakage

Made of polytetrafluoroethylene (PTFE) with excellent chemical and high temperature resistance.

PTFE rods are available in an approximate range of diameters from 3mm to 100mm and lengths typically between 500mm and 2000mm.

Pre-sintered PTFE is supplied before final sintering, allowing you to shape or form the material first. Fully sintered PTFE has already completed the thermal cycle and is typically used as a finished or semi-finished part.

No. Pre-sintered PTFE is not designed for melt processing. You normally use pre-sintered PTFE in cold forming processes followed by final sintering.

You should store pre-sintered PTFE in clean, dry conditions to avoid contamination before forming. Handling practices should align with your forming and sintering workflow.

Yes. Pre-sintered PTFE is commonly selected for custom parts where shaping, sintering, and machining are part of the production route. Material selection depends on forming method and part design.

When sourcing pre-sintered PTFE, you usually receive a technical data sheet, batch reference information, and basic quality documentation to support internal evaluation and approval.

If you source pre-sintered PTFE as a replacement, you may also need a backup option

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@peflon.com”.